“WE ARE WHAT WE REPEATEDLY DO. EXCELLENCE, THEN, IS NOT AN ACT, BUT A HABIT.” – ARISTOTLE

The Department of Mechanical Engineering is committed to and has proved its excellence in research, teaching, assistance to industry and service to the community. Started along with the inception of the college in the year 2002, our Department is recognised by academic peers, students and their employers as one of the best centres of Mechanical Engineering education and research. A degree in Mechanical Engineering is a prerequisite for a career in Automotive, Aerospace, Manufacturing, Building, Process, Medical and Marine domain. Many of our graduates go on to build careers that make important contributions to society in terms of wealth generation, safety and environmental sustainability. Department of Mechanical Engineering has got accreditation in the years 2012, 2019 and 2022.

Faculty in the department are at the forefront in research activities and this enables them to keep their teaching effective. The department boasts of a quarter of their Faculty who had a stint with multinational companies and core industries which very few colleges can stake claim of. This right mix of Academicians and Professionals reverberates in every activity of the department. Presently the department offers B. Tech in Mechanical Engineering, M. Tech in Advanced Manufacturing & Production Management and PhD Program, is led by Dr. Binoy Baby along with 25 Faculty and 10 laboratory Staff Members. 28% of the Faculty are Ph.D holders and 40% are pursuing Ph.D and doing research works in our department. Department of Mechanical Engineering is an Approved Research Centre of APJAKTU and researches are going on under the supervision of approved Guides. Funded projects from ANERT and APJAKTU-CERD are going on in the department. Professional Clubs such as SAE-INDIA, ASME, ISNEE and ISJHMT have active chapters which conduct national and international programs. Students are encouraged to participate in the SAE-BAJA, Mega ATV, ASME and ISNEE National and International Competitions. Department has signed MoUs with companies like Hindustan Machine Tools, Sea Blue Shipyard, Glenrock and Steel India to enhance industrial interactions and internships. Research Laboratory, Lab Facilities, Project Room, Heritage Diesel Engine and Museum are some of the attractions of our Department. Department offers B. Tech Honours and B. Tech-Minor in Industrial Engineering. The Faculty of the department gave their fair share to entrepreneurship by forming a start-up in the campus.

- To follow a teaching-learning process, with the support of qualified and committed faculty, in undergraduate and postgraduate Mechanical Engineering programmes .

- To establish an infrastructure and academic ambience for collaborating with Industry, Academia and Community to serve local and national enterprises.

- To make the students self-learners and socially committed engineers, for individual and collective accomplishments.

The graduates will:

- Have strong design and analysis skills in the theoretical and practical domains of Mechanical Engineering.

- Become leading professionals, as individuals, as well as team members, in a wide range of Mechanical Engineering and related fields.

- Exhibit ethical values and a strong spirit of social commitment to accelerate societal development.

PSO1: Graduates of the program will be able to apply Mechanical Engineering knowledge and skills to develop optimum solutions to problems in the areas of Design, Thermal, Manufacturing, Industrial Engineering and Management.

PSO2: Graduates of the program will be able to identify and adopt advancements in Mechanical Engineering for academic, industrial and social applications.

COURSES WE OFFER

B. Tech Mechanical Engineering (ME)

An Engineering program which seamlessly articulates the concepts from basic science to technology with relevant practice through lab and projects for building the problem solving skills, keeping industry requirements in place for Design, Manufacturing, Thermal etc specialization.

M.Tech in Advanced Manufacturing and Production Management

Learners are matured in a specific area of specialization by extending their prior know how through meticulous set of advanced courses with a dissertation to showcase their research potential. The focus for thesis is to solve an industry centric problem.

INITIATIVES BEYOND CLASS ROOM

R&D CENTRE

The Kerala Technological University has selected, Dept. of ME, SJCET as one of the research centres under the university. Currently, in this centre works are being carried out in the various fields under the guidance of Dr. Binoy Baby, Dr. Rajesh Baby, Dr. Lijo Paul, Dr. Jilse Sebastian, Dr. Nidhish M Nidhiry, Dr. Girinath B.

ADD ON & CERTIFICATION COURSES

The complete development of a Mechanical Engineer could only be accomplished by providing them with courses suiting to the present requirements in the industry. As technology advances day by day the tools that are used in the industry are also getting advanced. To help students acquire knowledge on such modern tools used in Industry, they are given trainings within the campus itself. The Mechanical Engineering Department of SJCET is offering various add on courses in NDT, Quality Control, Softwares like SOLID WORKS, CATIA, ANSYS etc. in collaboration with external agencies.

R&D LAB

Research ventures are inevitable to tackle the evolving challenges in the society as well as for the continuous improvement of knowledge and skill sets. Here at the Dept. of Mechanical Engineering a full-fledged R&D lab is provided for carrying out the research works of students and faculties. The lab is equipped with advanced hybrid micro machining setups, 3D printing machines, different types of fuel cells, fuel cell stacks & different types of heat pipes and it serves as the backbone for the development of several ostentatious products each year.

PROFESSIONAL SOCIETIES AND ASSOCIATIONS

SAE COLLEGIATE CLUB

In association with SAE India, a collegiate club for the automotive enthusiasts in St Joseph’s College of Engineering & Technology was started in the year 2011. The club was inaugurated by the then Project Director of the college, Dr. P J George. From the very first day of its inception, the club serves as a platform for sharing and disseminate knowledge among the students as well as faculties.

The Club regularly organizes meetings, invited talks and exhibitions that cover all aspects of technology related to design, manufacture, and total life cycle technology for the automotive and other related mobility industries.

ASME STUDENT CHAPTER

The ASME SJCET student chapter at the college was formed on 25th January, 2018 with the motto “Excellence is our obsession” and “Synergy at work”. The chapter focuses on providing training to the students to become experts in learning; on encouraging innovation and excellence in students through various means; on promoting better career development opportunities and services for students; on arranging expert industrial and research lectures; on extending full support for all the national seminars and technical events in the college; and on enhancing the self-confidence and self-esteem of students.

For more details visit asme.sjcetpalai.ac.in

MEA

Mechanical Engineering Association (MEA) is a unified platform where ideas of both faculty as well as students of our department are shared and new thoughts are generated. MEA have been actively conducting programmes from its inception. Programmes include Technical Sessions, Hands On Workshops, Conferences, Seminars, Project Presentations, Mechaura, Quiz Competitions, Design Contests etc.

ISHMT STAFF & STUDENT CHAPTER

ISHMT staff and student chapter of SJCET, Palai, was inaugurated on 30/03/2019 by Dr. S Sunil Kumar, Deputy Director LPSC and president of ISHMT Regional Chapter Trivandrum. The main objective of ISHMT is to promote the Science and technology of heat and mass Transfer. This Chapter, through organising Workshops, invited talks is focused on providing a common platform for the members to interact with industrialists, technologists, scientists and on fostering the advancement of science and applications of Heat and mass Transfer.

ISNEE SJCET

ISNEE SJCET student chapter is an organization that provides a platform to all the Engineering students to steer their path towards Technical and Managerial expertise. ISNEE’s design challenges like Go Kart Design Challenge, Quad TORC, and Formula Green; with phenomenal competitive stages guide every participant to empirical glory. The organization aims in bridging the gap between the academy and industry by offering a series of design competitions and skill development programs to the students where they can learn and implement the knowledge gained while in the classroom.

VIDEO LECTURES BY FACULTY MEMBERS

OUR STRENGTH

ALUMNI TALK SERIES

In order to inspire younger generations at SJCET, Department of Mechanical Engineering, in association with ASME and MEA is rolling out a series of invited talks of experts from various fields who are SJCET alumni.

Talk on ‘ Application Knowledge And Career Opportunities in Steam Engineering’ by Mr. Dileep Cheriyan (M.Tech AMPM Alumni), Team Lead, FORBES MARSHALL Pvt Ltd.

Talk on “Sustainable Mobility Solution” by Mr. Jacob Thekkekara (2002-2006 Batch), CTO, Co-founder Pi Beam Labs Pvt. Ltd and also an Alumnus of SJCET Mechanical Engineering Department. Talk is organised by ASME in association with MEA.

Ph.D in MECHANICAL ENGINEERING

The college is Research Centre of APJ Abdul Kalam Technological University (KTU).Candidates qualifying the KTU’s Entrance procedure can join for Ph.D under the approved guide in the college

Approved Guides

ACTIVITIES & ACHIEVEMENTS

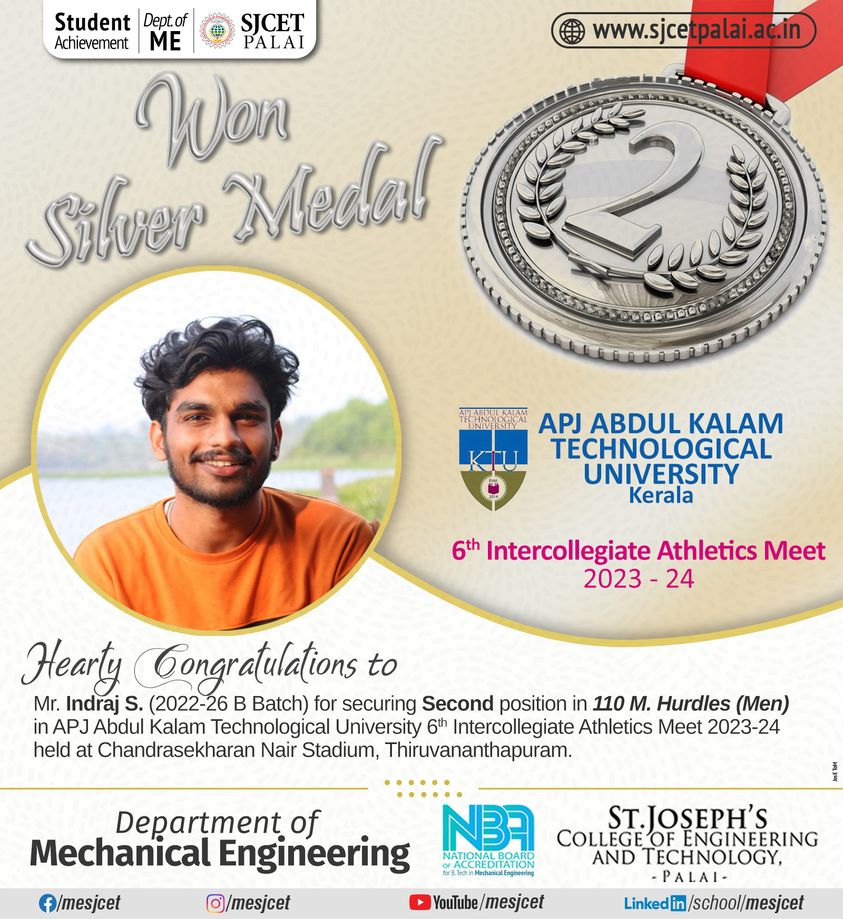

Achievements by Students

- Team Rognation, the only team from Kerala that dared to dream and succeeded in getting into the Indian Karting Championship! With their grit and determination, they overcame all the technical rounds. Their hard work paid off, earning them an impressive 6th position in the 150cc All India ranking. For first-timers, this is more than just winning a championship – it’s a testament to their passion and commitment to excellence.

- Bilbin Mathew (S8 ME), Mr. Paul Vargheson(S8 ME), Mr. Alan Philip Rajan(S8 ME) and Mr. Mohammed Yasim of B. Tech 2018 – 2022 batch under the Guidance of Dr. Rajesh Baby (Dean – Research) and Dr. George Tom Varghese (Head – Dept. of Electronics & Instrumentation Engineering) received Financial Assistance to Student Projects under CERD student project scheme for the project – Development of an automatic height adjusting pillow to relieve chronic neck pain (cervicalgia) from APJ Abdul Kalam Technological University, Kerala

- Thimothy Benny, Mr. Akhil Krishnan, Mr. Genesis J Cheruvallil and Mr. Benchamin Tomy of B.Tech 2018 – 2022 ME batch under the Guidance of Mr. lvin Jose (Assistant Professor) received Financial Assistance to Student Projects under CERD student project scheme for the project -Tool design and fabrication of hybrid electro discharge grinding setup for microchannels from APJ Abdul Kalam Technological University, Kerala.

- Derek Joe(20-24 ME) won 2ndposition in Diagrammatic Reasoning, SPECTRA 21

- Aswin S (18-22 ME), Allen Mathews(19-23 ME), Shibin Bijomy Joseph(18-22 ME), won 1st 2nd and 3rd positions in Group Discussion Competition, SPECTRA 21

- Anish George(18-22 ME), Jobin Chacko Sebastian(18-22 ME) were winners of TECHUMINATI organised by SAE INDIA collegiate club of SJCET as part of the SPECTRA’21

- Arjun Kumar of 20-24 ME, won 2nd prize in VIGNETTE Drawing Competition organised by SAE INDIA collegiate club of SJCET as part of the SPECTRA’21

- Benjamin Tomy(18-22 ME), Jobin George(19-23 ME), Ron Binoy(19-23 ME) & Athul Vijay(20-24 ME) were winners of CAD MANIA organised by SAE INDIA collegiate club of SJCET as part of the SPECTRA’21

- Savinoj Thomas of 20-24 ME A, won 3rd prize in quiz organised by SAE INDIA collegiate club of SJCET as part of the SPECTRA’21

- Arun Alex got selected as community leader of central zone of Innoators Premiere League(IPL) introduced by Kerala Startup Mission & IEDC Kerala.

- Josh Josit got ‘Mikacha Yuva Karshakan’ Award from Thidanad Grama Panchayat.

- Arnold Shaiju & Antony Senson of 20-24 ME won prizes in ANWESHA, an online project submission competition of IEEE

- Sandra Susan Biju is placed in FAURECIA. She is one among the only two candidates selected from Kerala. Faurecia S.E. is a th French global automotive supplier headquartered in Nanterre, Paris. In 2018, it was the 9 largest international automotive parts manufacturer in the world and #1 for vehicle interiors and emission control technology. It designs and manufactures seats, exhaust systems, interior systems and decorative aspects of a vehicle

- Bilbin Mathew & Emmanuel Shaji of S6 ME A bagged second prize in ‘Lathe Thread Cutting And Taper Turning Competition’ of SAEINDIA Tier -III Competition (National Level). They were the winners in Tier-II competition held at TKMCE last year.The much delayed competition was held yesterday in online mode.

- Team BRAVO [Tyroveloce Racing] of Department of Mechanical Engineering – SJCET, Palai achieved 18th position nationwide and 2nd position statewide in the Mega ATV Championship conducted by Autosports India at Pernem, Goa.

- Darshan Pratheep, Elvin Pious, Jobin Mathew, George Hawkins, Mr. Peter Jose & Dr. Binoy Baby received Patent for Arrowroot Grinding Machine. Dr. Jeeno Mathew was their Faculty Advisor.

- 45 students of 17-21 ME batch got certified in Quality Assurance and Quality Control through in-house job oriented certification programme.

- Edwin S Pananthanam of 16-20 ME Batch became one among the 170 SOLIDWORKS Champions worldwide.

- Ebin Shibu James of 16-20 Batch and Ashish Devasia of 17-21 Batch conferred Section Award (Kerala) of SAEINDIA Foundation along with a scholarship for their ·outstandng achievement as an Engineering Student in Mobility field. They are among the only 3 students who have received this award.

- Team BRAVO [Tyroveloce Racing] of Department of Mechanical Engineering – SJCET, Palai achieved 18th position nationwide and 2nd position statewide in the Mega ATV Championship conducted by Autosports India at Pernem, Goa.

- Bilbin Mathew & Emmanuel Shaji of S6 ME A bagged second prize in ‘Lathe Thread Cutting And Taper Turning Competition’ of SAEINDIA Tier -III Competition (National Level). They were the winners in Tier-II competition held at TKMCE last year.The much delayed competition was held yesterday in online mode.

- Sandra Susan Biju is placed in FAURECIA. She is one among the only two candidates selected from Kerala. Faurecia S.E. is a th French global automotive supplier headquartered in Nanterre, Paris. In 2018, it was the 9 largest international automotive parts manufacturer in the world and #1 for vehicle interiors and emission control technology. It designs and manufactures seats, exhaust systems, interior systems and decorative aspects of a vehicle.

- Ashish Devasia, 2020 Mega ATV Vice Captain got a rare ‘Internship Opportunity’ at Altair Inc. for a period of 1 month with a dedicated guide. On successful completion, they may absorb him as employee/project engineer.

- Kevin Jose, Midhun MT,Joel Bijosh,Arjun MP.“EXPERIMENTAL INVESTIGATION OF WATER COOLED MINICHANNEL HEAT SINK FOR CENTRAL PROCESSING UNIT COOLING International Colloquium on Recent Trends in engineering at MA college of engineering”. March 3-4 2020

- Experimental analysis of the influence of discharge gap on EDM performance – J Jose, L Paul

- Design and development of orthosis for clubfoot correction in infants an additive manufacturing approach, VSA Vishnu, T Zacharia, L Paul, Materials Today: Proceedings 27, 2605-2608

- Machining characteristics of micro-magnetic field assisted EDM (µ-MFAEDM), R Renjith, L Paul, Materials Today: Proceedings 27, 2000-2004

- Experiment on pollution control in µ-abrasive jet machining using liquid films, PS Vishnu, PV Pradeep, L Paul, Materials Today: Proceedings 27, 2033-2036

Achievements by Faculty

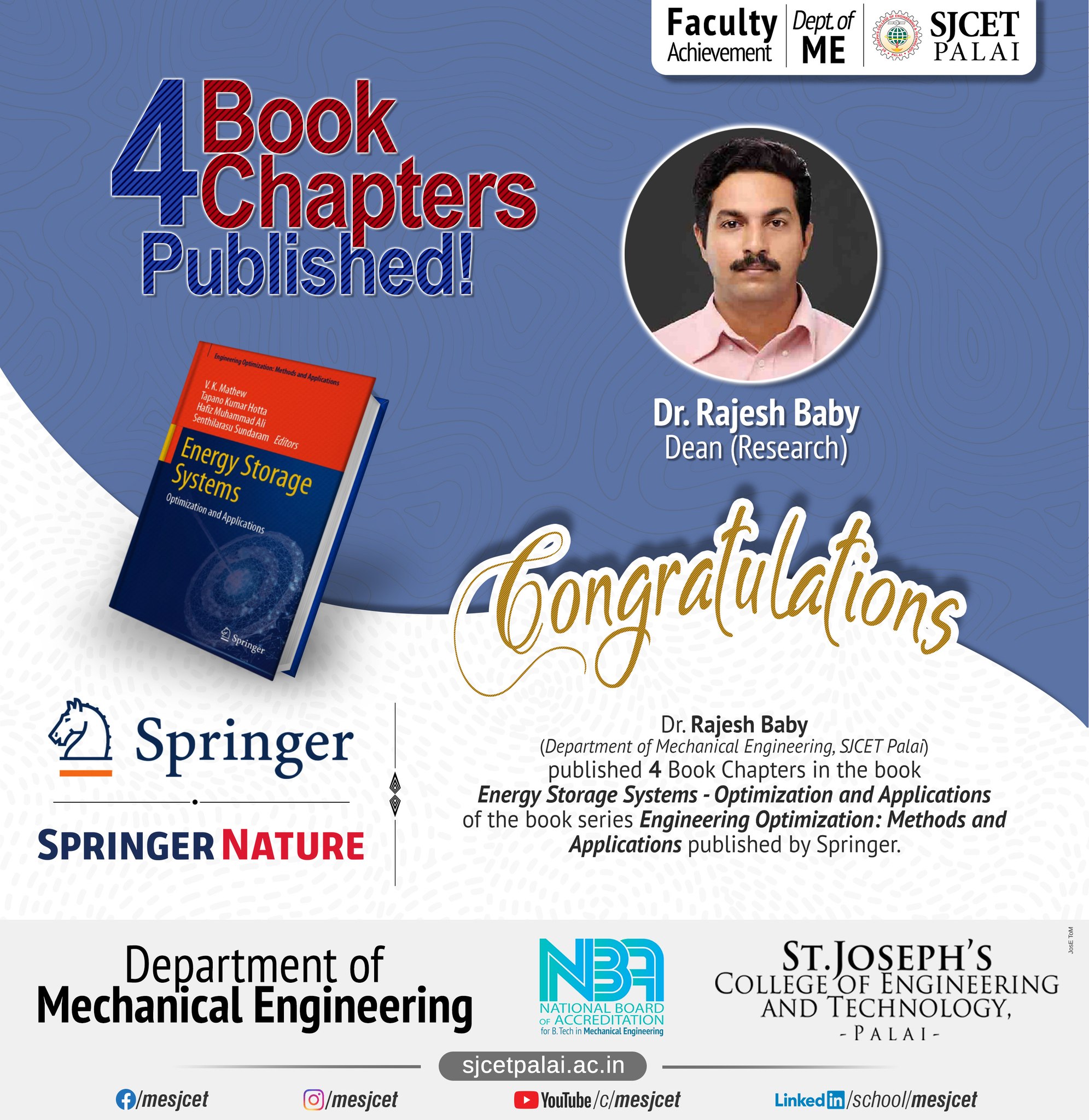

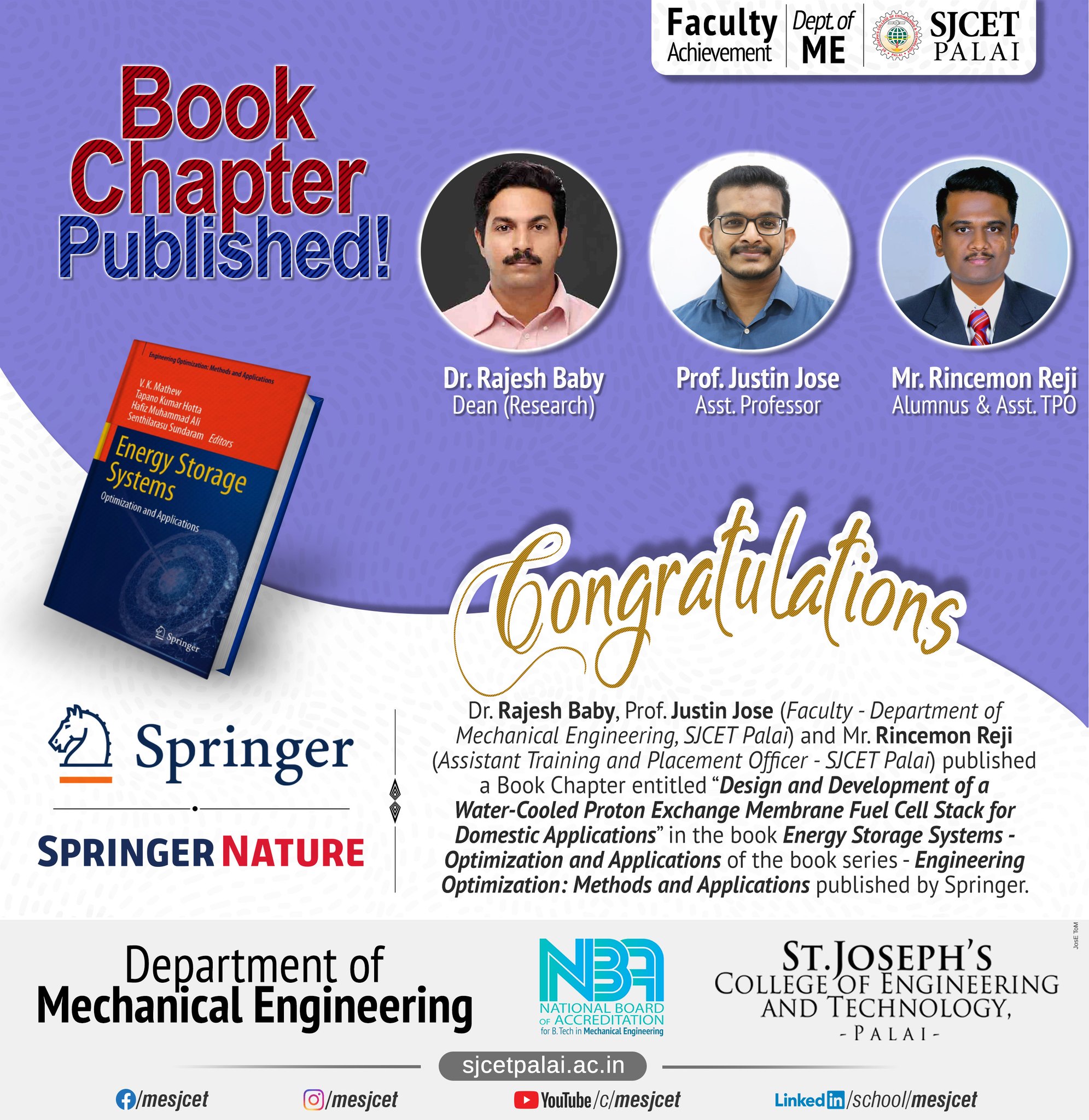

- Dr. Rajesh Baby, Prof. Justin Jose and Mr. Rincemon Reji published a Book Chapter entitled “Design and Development of a Water-Cooled Proton Exchange Membrane Fuel Cell Stack for Domestic Applications” in the book Energy Storage Systems – Optimization and Applications of the book series – Engineering Optimization: Methods and Applications published by Springer.

- Dr. Rajesh Baby (Department of Mechanical Engineering, SJCET Palai) published 4 Book Chapters in the book Energy Storage Systems – Optimization and Applications of the book series Engineering Optimization: Methods and Applications published by Springer.

- Prof. Babusanker S. and Dr. Rajesh Baby (Department of Mechanical Engineering, SJCET Palai,) got approval for research funding of Rs.15, 10,615 from ANERT for the project “Design, fabrication and implementation of PCMs based passive cooling system for Thermal Management of Li-ion Batteries used in Electric Vehicles”

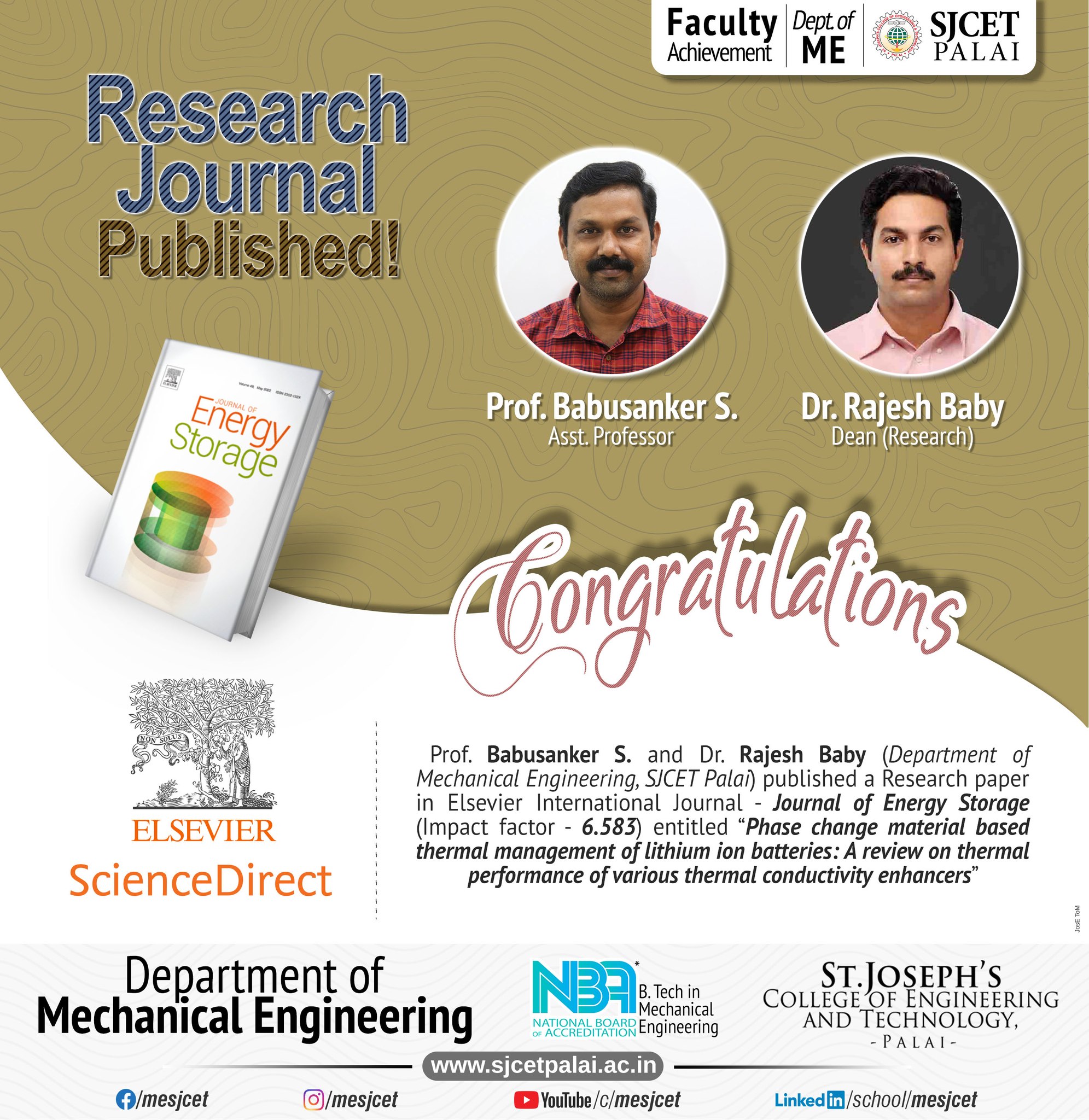

- Babusanker S. and Dr. Rajesh Baby, ME Dept. published a Research paper in Elsevier International Journal – Journal of Energy Storage (Impact factor – 6.583) entitled “Phase change material based thermal management of lithium ion batteries: A review on thermal performance of various thermal conductivity enhancers”

- Jeeno Mathew won the Best Teacher Award in Art of Teaching competition (Clarity & Concepts) conducted by GTECH(Group of Technology Companies), Kerala with APJAKTU as university partner.

- A total sum of Rs. 14 Lakhs is sanctioned by AICTE as a grant in aid for the project titled ‘Design & Development of Patient Specific Biomedical Devices using SLA Additive Manufacturing with Bio plastics’ under the research promotion scheme(RPS) to Dr. Lijo Paul & Dr. Jilse Sebastian.

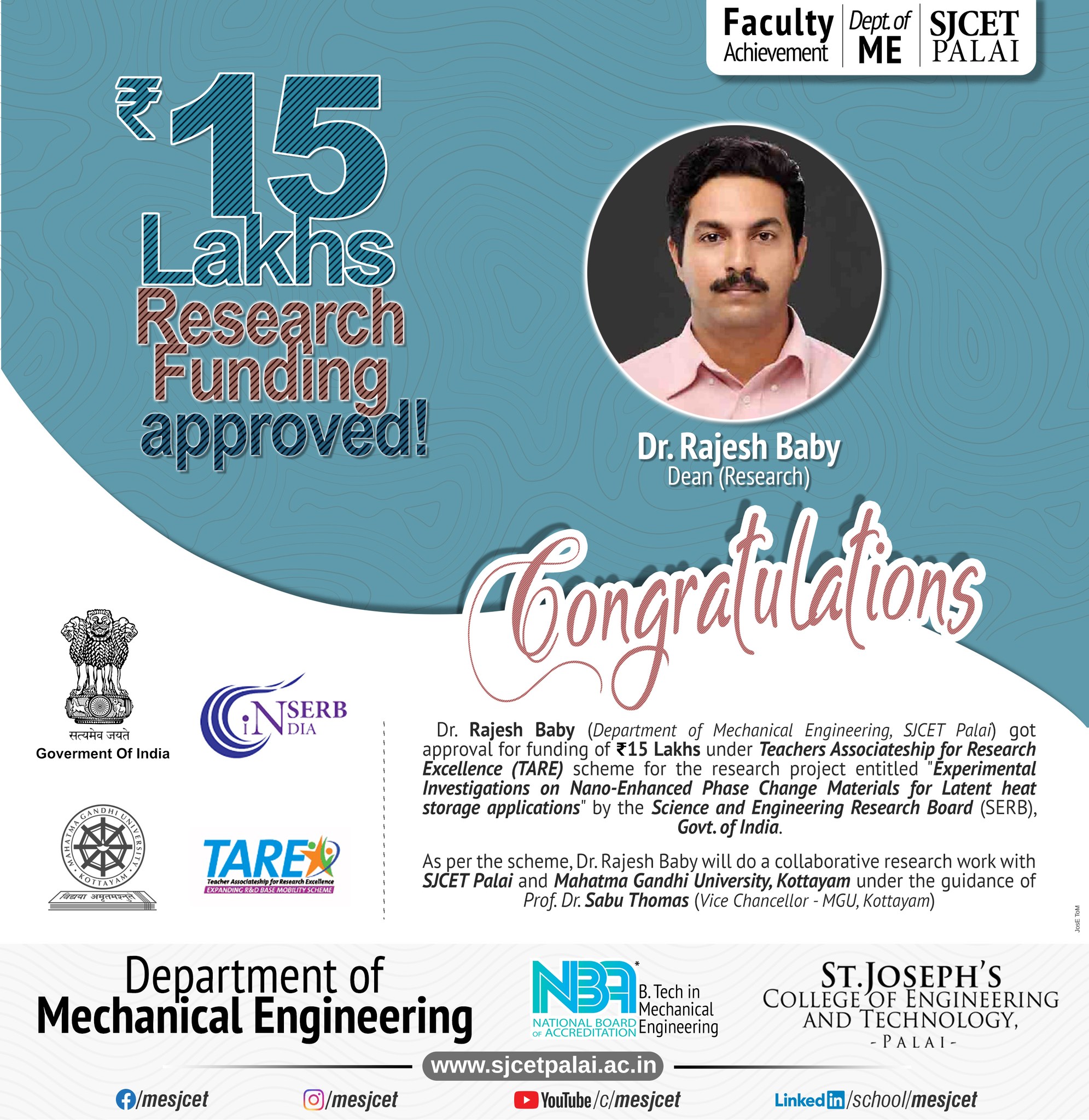

- Dr.Rajesh Baby, Dean(Research), got approval of the research project proposal entitled “Experimental Investigations on Nano-Enhanced Phase Change Materials for latent heat storage applications” by the Science and Engineering Research Board (SERB),Govt. of India, for funding of Rs.15 Lakhs under Teachers Associateship for Research Excellence (TARE) scheme. As per the scheme Dr.Rajesh Baby will do a collaborative research work with SJCET and Mahatma Gandhi University, Kottayam with the guidance of Dr.Sabu Thomas, Vice Chancellor.

- Dr. B Girinath’s paper ‘Experimental studies on friction stir welding” is accepted for publication in SAGE journal – Journal of Materials: Design and Applications (SCIE indexed, Impact factor: 2.311)

- Prof. Tom Zacharia is recognised as one among the World’s Top Scientist by Stanford University, USA and Elsvier Publications, Netherlands. He is one among the 39 from Kerala. Govt. of Kerala and Kerala State Council for Science, Technology & Environment felicitated him.

- Dr. Jeeno Mathew published a research paper in SCIE & SCOPUS indexed international journal – Journal of Scientific & Industrial Research(IF -1.056) entitled ‘A Mathematical and Heuristic Approach for Scheduling Repetitive Projects in a Bi-Objective Single Crew Model’ by CSIR Publications.

- Dr. Jilse Sebastian, Associate Professor, Department of Mechanical Engineering has been selected as the Chairman of SAEINDIA Division Management Committee- Cohin.

- Mr. Dinu George has got approval for financial support ass Research Seed Money(RSM) of Rs.110000, from Centre for Engineering Research & Development(CERD) of APJ Abdul Kalam Technological University, Kerala. His research is on Photo-Voltaic Thermal(PVT) collector integrated mixed mode drying system with PCM based thermal storage for drying of Cassava.

- Dr. Binoy Baby’s work titled ‘Experimental Investigation of the Performance of a BIPV/Thermal Collector assisted indirect Solar Dryer with PCM based Thermal Storage’ got selected for preliminary screening in the R&D proposals pertaining to “Solar PV” by ANERT.

- Dr. Rajesh Baby’s work titled ‘Design Fabrication & Implementation of PCMs based Passive Cooling System for Thermal Management of Li ion Batteries used in Electric Vehicles’ got selected for preliminary screening in the R&D proposals pertaining to “Solar PV” by ANERT.

- Mr. Dinu George’s work on ‘Experimental Investigation of a Photo-Voltaic Thermal (PVT) Collector Integrated Mixed Mode Drying System with PCM based Thermal storage for drying of Cassava’ got shortlisted for presentation in RSM 2021 on 18-5-21.

- Dr. Lijo Paul acquired intimation of approval of grant of Rs. 50,000/- (Rupees Fifty thousand only) to conduct Conference under the scheme Grant for Organizing Conference (GOC).

- Dr. B. Girinath (Assistant Professor, Department of Mechanical Engineering) published a Research paper in international journal Welding in the World (Impact factor: 1.589) entitled “Fabrication, Characterisation, and finite element analysis of cold metal transfer-based wire and arc additive-manufactured aluminium alloy 4043 cylinder” by Springer Publications.

- Mr. Bony John published a technical paper in international journal -Energy (Impact factor: 6.082) by Elsevier Publications, entitled “Sizing and techno-economic analysis of hydrokinetic turbine based standalone hybrid energy systems”.

- Dr. Lijo Paul (Dean PG) published a technical paper in international journal – Silicon (Impact factor: 1.499) by Springer Publications, entitled “Model Prediction and Experimental Study of Material Removal Rate in Micro ECDM Process on Borosilicate Glass”.

- Dr. Lijo Paul (Dean PG) published a technical entitled ” Relevance of micromachining in microfluidics and biomedical devices” in Elsevier Publications.

- Dr. Lijo Paul and Dr. Jilse Sebastian authored a chapter in the book – Sustainable Manufacturing [Handbooks in Advanced Manufacturing] published by Elsevier Publications.

- Dr. Lijo Paul work ‘Relevance of micromachining in microfluidics and biomedical devices’ got published on Elsevier.

- Dr. Lijo Paul work ‘Model Prediction and Experimental Study of Material Removal Rate in Micro ECDM Process on Borosilicate Glass’ got published on Springer Netherlands.

- Dr. B Girinath’s research article ‘A modified version of MATLAB application window for predicting the weld bead profile and stress–strain plot of AA5052 CMT weldment using ER4043’ got published in SIMULATION journal (SciSearch indexed), SAGE Publication. Impact factor (1.377)

Dr. Lijo Paul and Mr. Ivin Jose published their work ‘Effect of discharge gap on EDM using desirability function analysis’ on Elsevier - Dr. B. Girinath has successfully completed doctrol degree on the topic “ Modeling & Experimental Analysis of Cold Metal Transfer Welding of AA5052 Sheet Metal” from NIT Tiruchirappalli.

- Dr. Giphin George has successfully completed doctoral degree on !he topic “Applicotions of Carbon Coated Zn-Al Layered Double Hydroxides in Textile Dye Adsorption and as o Counter Elecrode Moteriol in Dye-nsitized Solar Cells” from VeUore Institute of Technology.

- Mr. Jeeno Mathew submitted his research thesis titled “Multi Objective Optimization for Scheduling Repetitive Projects” to MG University.

- Dr. Lijo Paul was Session Chair for contributory oral presentations on 22 April 2021 at AICTE Sponsored International Conference on Sustainable materials, Manufacturing and Renewable Technologies (i-SMaRT 2021) organized by the Department of Mechanical Engineering, Federal Institute of Science and Technology (FISAT) on 22- 23 April 2021.

- Mr. Jeeno Mathew received Best paper award for his work “An ABC based approach to minimize total project cost in a repetitive project” at ICISTSD 2020 Nov 23,24.

- Mr. Jeeno Mathew has successfully completed doctoral degree on the topic “Multi Objective Optimization for Scheduling Repetitive Projects” from MG University Kottayam.

- With reference to the proposal submitted by Mr. Sachin Jose along with Mr. Sarju S, our college received the sanction for the payment of Rs. 100000 under the ‘Scheme for Promoting Interests, Creativity and Ethics among Students (SPICES)’.

- Mr. B. Girinath, Asst. Professor, Dept. of ME, published a research article titled ‘Studies on influence of torch orientation on microstructure, mechanical properties and formability of AA5052 CMT welded blanks’ in the journal Archives of Civil and Mechanical Engineering (SCIE) published by Springer.

- Dr. J Babu, Professor ME Dept. and Dr. Lijo Paul, Assoc. Professor, ME Dept. published a book chapter on ‘High Speed Machining of Composite Materials’ in prestigious Elsevier Publications.

- Dr. Binoy Baby (Professor, ME Dept.) and Mr. Don George Kurian (Asst. Professor, ME Dept.) along with Minil Roy, Neseef Azeez, Nithin Babu and Robin Tomy of 2013-17 ME Batch of SJCET Palai acquired a Patent for the Fish Descaling Machine they developed from the Controller General of Patents, Designs & Trademarks, Govt. of India.

- Mr. Bony John, Assistant Professor, ME Dept., published a paper entitled ‘Integration of hydrokinetic turbine-PV-battery standalone system for tropical climate condition’ in the Renewable Energy International Journal (Impact Factor – 5.44) by Elsevier publications.

- Mr. Anooplal B. got approval for a funding of Rs. 1.2 Lakhs for his works on ‘PCM based thermal management of Li-ion battery’ under the APJAKTU-CERD-Research Seed Money Scheme.

- Mr. Pradeep P. V. got approval for a funding of Rs. 1.4 Lakhs for his works on ‘Additive manufacturing of biodegradable and photocurable elastomer and polymer based composites’ under the APJAKTU-CERD-Research Seed Money Scheme.

- Mr. Shiblemon K. V. got approval for a funding of Rs. 1.35 Lakhs for his works on ‘Investigations on heat transfer enhancements in micro channel heat sinks’ under the APJAKTU-CERD-Research Seed Money Scheme.

- Girinath B., Assistant Professor, ME Dept. successfully completed his doctoral degree in ‘Modeling & Experimental Analysis of Cold Metal Transfer welding of AA5052 Sheet Metal” from NIT Tiruchirappalli.

- Mr. B. Girinath, Asst. Professor, Dept. of ME, published a research article titled ‘Studies on influence of torch orientation on microstructure, mechanical properties and formability of AA5052 CMT welded blanks’ in the journal Archives of Civil and Mechanical Engineering (SCIE) published by Springer.

- Dr. J Babu, Professor ME Dept. and Dr. Lijo Paul, Assoc. Professor, ME Dept. published a book chapter on ‘High Speed Machining of Composite Materials’ in prestigious Elsevier Publications.

- Dr. Binoy Baby (Professor, ME Dept.) and Mr. Don George Kurian (Asst. Professor, ME Dept.) along with Minil Roy, Neseef Azeez, Nithin Babu and Robin Tomy of 2013-17 ME Batch of SJCET Palai acquired a Patent for the Fish Descaling Machine they developed from the Controller General of Patents, Designs & Trademarks, Govt. of India.

- Mr. Bony John, Assistant Professor, ME Dept., published a paper entitled ‘Integration of hydrokinetic turbine-PV-battery standalone system for tropical climate condition’ in the Renewable Energy International Journal (Impact Factor – 5.44) by Elsevier publications.

- Mr. Anooplal B. got approval for a funding of Rs. 1.2 Lakhs for his works on ‘PCM based thermal management of Li-ion battery’ under the APJAKTU-CERD-Research Seed Money Scheme.

- Mr. Pradeep P. V. got approval for a funding of Rs. 1.4 Lakhs for his works on ‘Additive manufacturing of biodegradable and photocurable elastomer and polymer based composites’ under the APJAKTU-CERD-Research Seed Money Scheme.

- Mr. Shiblemon K. V. got approval for a funding of Rs. 1.35 Lakhs for his works on ‘Investigations on heat transfer enhancements in micro channel heat sinks’ under the APJAKTU-CERD-Research Seed Money Scheme.

- A book (monograph) entitled ‘Thermal Management of Electronics, Volume I: Phase Change Material-Based Composite Heat Sinks—An Experimental Approach‘ by Dr. Rajesh Baby and his Research Guide Prof. C. Balaji has been published by Momentum Press, New York.

- Kerala State Council for Science, Technology & Environment (KSCSTE) sanctioned to release an amount of Rs. 10,000 towards financial assistance for implementing the project entitled ‘Plastic Rope Making Machine Using Plastic Bottles’ under the leadership of Dr. Lijo Paul

- Dr. Lijo Paul, Associate Professor, Dept. of ME got approval for a funding of Rs.130,000 for his work on ‘Performance Optimization of Micro Abrasive Jet Machining’ under the APJAKTU-CERD-Research Seed Money Scheme.

- Dr. Rajesh Baby, Associate Professor of ME Dept. received a funding of Rs. 1.2 Lakhs for the project titled ‘Experimental Investigations and Performance Optimization of the Bipolar Plates of Proton Exchange Membrane Fuel Cells’ under the APJ-KTU-CERD Research Seed Money Scheme.

- Prof. Tom Zacharia has been awarded a funding of Rs. 27 Lakhs from DST under the scheme IDP (Industrial Development Scheme) for his work on ‘Design and Fabrication of Extrusion Machine’. This is a first time achievement among all engineering colleges in Kerala.

Projects Undertaken by Faculty / Students

- Prof. Babusanker S. and Dr. Rajesh Baby (Department of Mechanical Engineering, SJCET Palai,) got approval for research funding of Rs.15, 10,615 from ANERT for the project “Design, fabrication and implementation of PCMs based passive cooling system for Thermal Management of Li-ion Batteries used in Electric Vehicles”

- Bilbin Mathew (S8 ME), Mr. Paul Vargheson(S8 ME), Mr. Alan Philip Rajan(S8 ME) and Mr. Mohammed Yasim of B. Tech 2018 – 2022 batch under the Guidance of Dr. Rajesh Baby (Dean – Research) and Dr. George Tom Varghese (Head – Dept. of Electronics & Instrumentation Engineering) received Financial Assistance to Student Projects under CERD student project scheme for the project – Development of an automatic height adjusting pillow to relieve chronic neck pain (cervicalgia) from APJ Abdul Kalam Technological University, Kerala

- Thimothy Benny, Mr. Akhil Krishnan, Mr. Genesis J Cheruvallil and Mr. Benchamin Tomy of B.Tech 2018 – 2022 ME batch under the Guidance of Mr. lvin Jose (Assistant Professor) received Financial Assistance to Student Projects under CERD student project scheme for the project -Tool design and fabrication of hybrid electro discharge grinding setup for microchannels from APJ Abdul Kalam Technological University, Kerala.

- Rajesh Baby,Dean(Research), got approval of the research project proposal entitled “Experimental Investigations on Nano-Enhanced Phase Change Materials for latent heat storage applications” by the Science and Engineering Research Board (SERB),Govt. of India, for funding of Rs.15 Lakhs under Teachers Associateship for Research Excellence (TARE) scheme. As per the scheme Dr.Rajesh Baby will do a collaborative research work with SJCET and Mahatma Gandhi University, Kottayam with the guidance of Dr.Sabu Thomas, Vice Chancellor.

- A total sum of Rs. 14 Lakhs is sanctioned by AICTE as a grant in aid for the project titled ;Design & Development of Patient Specific Biomedical Devices using SLA Additive Manufacturing with Bio plastics’ under the research promotion scheme(RPS) to Dr. Lijo Paul & Dr. Jilse Sebastian.

- Dinu George has got approval for financial support ass Research Seed Money(RSM) of Rs.110000, from Centre for Engineering Research & Development(CERD) of APJ Abdul Kalam Technological University, Kerala. His research is on Photo-Voltaic Thermal(PVT) collector integrated mixed mode drying system with PCM based thermal storage for drying of Cassava.

- Mr. Anooplal B. got approval for a funding of Rs. 1.2 Lakhs for his works on ‘PCM based thermal management of Li-ion battery’ under the APJAKTU-CERD-Research Seed Money Scheme.

- Mr. Pradeep P. V. got approval for a funding of Rs. 1.4 Lakhs for his works on ‘Additive manufacturing of biodegradable and photocurable elastomer and polymer based composites’ under the APJAKTU-CERD-Research Seed Money Scheme.

- Mr. Shiblemon K. V. got approval for a funding of Rs. 1.35 Lakhs for his works on ‘Investigations on heat transfer enhancements in micro channel heat sinks’ under the APJAKTU-CERD-Research Seed Money Scheme.

Industry- Institute Interactions (MOU)

- An MoU is executed on 8-6-2019 between HMT Machine Tools Limited, Kalamassery & SJCET with an objective to impart skill development on CNC Programming & Operation, Assembly of Machines, Manufacturing Process, Quality Control & Inspection & Foundry Technology for the 2nd, 3rd and 4th year students of ME & EEE departments of SJCET.

- Dept. of Mechanical Engineering, St. Joseph’s College of Engineering and Technology, Palai has signed MOU with Steel India Palai. This MOU will help our students to design and develop products relevant for the market. Director of Steel India Pala, Fr. Joseph Thazhathuvarikayil and College Chairman Msgr. Dr. Joseph Maleparambil shared the MOU in the presence of Fr. Mathew Koramkuzha, Manager SJCET, Dr. J David, Principal SJCET, Dr. Binoy Baby, HoD ME, Prof. Tom Zacharia, Dr. Saji Abraham, Prof. Sachin Jose and Prof. Alex Chollackal.

- Department of Mechanical Engineering entered into a strategic technological alliance with Glenrock Rubber Products Pvt. Ltd. – An alliance which offers exposure to production floor, interaction with professionals and assimilate a corporate life.

- Dept. of ME signed an MoU with Sea Blue Shipyard Ltd. This association will help students to get an idea on ship building & repairs, life at sea and working of a ship.

Patents Obtained

- The project titled “Design and Fabrication of Separator Machine” intended to separate mace from nutmeg obtained Design Patent from Govt. of India. The project team members include Mr. Bissmon Thomas, Mr. Ajith Payampallil Jose, Mr. Antony Jose and Mr. Akash Joseph (2018 ME Batch) who under the supervision of Dr. Jilse Sebastian and Dr. Binoy Baby.

- Darshan Pratheep, Elvin Pious, Jobin Mathew, George Hawkins, Mr. Peter Jose & Dr. Binoy Baby received Patent for Arrowroot Grinding Machine. Dr. Jeeno Mathew was their Faculty Advisor.

- Dr. Binoy Baby (Professor, ME Dept.) and Mr. Don George Kurian (Asst. Professor, ME Dept.) along with Minil Roy, Neseef Azeez, Nithin Babu and Robin Tomy of 2013-17 ME Batch of SJCET Palai acquired a Patent for the Fish Descaling Machine they developed from the Controller General of Patents, Designs & Trademarks, Govt. of India.

.

INNOVATIONS BY THE FACULTY IN TEACHING AND LEARNING

PROTON EXCHANGE MEMBRANE (PEM) FUEL CELL TESTING

A video describing the Proton Exchange Membrane (PEM) fuel cell testing done by the Mechanical Engineering Department of St.Joseph’s College of Engg. & Tech., Palai is prepared. The video is uploaded in YouTube (a link is provided in the college website). As a similar video is not existing, the video will help the interested students and researchers to get more clarity in the working of fuel cells.

HERITAGE DIESEL ENGINE

Heritage Diesel Engine is a 68 years old, open type, heavy Diesel Engine situated in the forefront of Thermal Engineering Laboratory at St. Joseph’s College of Engineering & Technology, Palai. It is an imported I.C. engine from Birmingham England by one of the rubber product industries (A.V.G. Group) at Kottayam where it was used as the power source for heavy machines drive line. The almost condemned machine was fully reconditioned by technical supporting staff of SJCET Palai in the year 2002. Students of SJCET now get opportunity to watch the live working of an I.C. Engine which add up to their practical knowledge. This video describes the real time working of the Heritage Diesel engine from engine start to engine stop which is beneficial to all enthusiastic students. The video is uploaded in YouTube (a link is provided in the college website).

MICRO ELECTRO CHEMICAL DISCHARGE MACHINE (µECDM)

Electro Chemical Discharge Machining (ECDM) has been developed as a hybrid machining process to machine electrically non-conducting and conducting materials effectively and efficiently. The material removal is mainly carried out with melting and vaporisation under thermal energy from spark generated from tool electrode and partially by chemical etching under the presence of an electrolyte. In this process basic principles of EDM and ECM are combined to overcome the limitations of the individual process. The EDM and ECM can machine only conducting materials whereas ECDM can machine both conducting and non-conducting materials effectively and efficiently. Commonly machined materials in ECDM include ceramic, composites, semi conducting materials like silicon to higher level of accuracy.

Objectives

To measure characteristics of the micro hole machined in terms of Material Removal Rate, Tool Wear Rate and Radial overcut. Also characterization of micro channels.

Outcome

ECDM process has shown good machining tool for drilling of glass substrates stainless steel materials, composites and ceramics. Fabrication of intricate micro features, precise dies deep hole drilling , dressing of micro tools in grinding etc. In the course of Micro and Nano Manufacturing for S8 ME, the same instrument can be preferred.

The video demonstration of Micro Electro Chemical Discharge Machine (µECDM) is uploaded in YouTube (a link is provided in the college website).

MICRO ELECTRO DISCHARGE MACHINE

The EDM process involves a controlled erosion of electrically conductive materials by the initiation of rapid and repetitive spark discharge between the electrode tool and work piece separated by a small gap of about 0.01-0.50 mm known as spark gap. The spark gap is either flooded or immersed under the dielectric fluid. The spark discharge is produced by the controlled pulsing of direct current between the work piece and tool. Micro EDM and EDM are similar in principles, and difference occurs in terms of the energy range and tool which is lower. The resolution of axis movement and discharge energy are in micron ranges for micro EDM process. Micro EDM is shown as an effective tool in machining extremely hard materials hard tungsten carbide and alloys of steel.

Objectives

To measure characteristics of the micro hole machine in terms of Material Removal Rate, Tool Wear Rate and Radial overcut. Also characterization of micro channels.

Outcome

Micro EDM has been used as an effective tool in fabricating micro electrode, gear patterns with Tungsten Carbide materials, micro compressor, micro turbine impellers , high aspect ratio micro arrays, biocompatible devices from Magnesium etc. In the course of Micro and Nano Manufacturing for S8 ME, the same instrument can be preferred.

The video demonstration of Micro Electro Discharge Machine is uploaded in YouTube (a link is provided in the college website).

MICRO ABRASIVE JET MACHINE

Abrasive Jet Machining (AJM) has become an effective tool for machining hard brittle materials with high intensity flow of abrasive particles. The size of abrasive decides the accuracy of the process and fine abrasives are used for finishing operations.

In AJM material is removed with kinetic energy of loose abrasives from workpiece. The commonly used medium is air. Abrasive mixture is directed through nozzle to workpiece. The tip of nozzle and workpiece should be kept within a small gap. The distance between nozzle and workpiece, diameter of nozzle and angle of impact influence the machining process. As the jet strikes on the surface micro plastic deformation happens on the workpiece and on further impact the material get eroded by chipping action. The brittle broken particles getting separated on the surface of the workpiece are taken away by the carrier gas.

Objectives

To measure the Material Removal Rate and Radial Overcut for a machined hole under given set of parameters.

Outcome

The AJM has found process application in cleaning, etching, cutting, deburring and polishing on of ceramic materials which are brittle in nature and is much cheaper than tradition wet etching processes. Micro fabrication of channels and holes on PMM areas is also carried out . AJM is also as an effective tool in microelectronic, optoelectronic devices and 3D structures on glass. In the course of Micro and Nano Manufacturing for S8 ME, the same instrument can be preferred.

The video demonstration of Micro Abrasive Jet Machine is uploaded in YouTube (a link is provided in the college website).

HOT AIR JET MACHINE

In hot air jet machining, the hot air jet issuing from a nozzle is impinged on the glass plate to be cut. The hot air jet or the X-Y coordinate table, on which the plate glass is placed, can be moved at the required speed. Any complex profile could be easily and economically generated in a single step by this method. A hot air jet is produced by using (a) a glass tube, (b) a compact hot air gun and (c) an electronic hot Air blower. In the preliminary experiments, a glass tube and a compact hot air gun are used. The compressed air is passed through the inlet passage and a hot air jet is obtained at the nozzle exit. The nozzles of different diameters are fitted (one at a time) at the outlet of the gun by varying the jet diameter. The required air flow rates and velocities are obtained by varying the supply air pressure on the system terminals. The air temperature is adjusted by adjusting the voltage supply to the electric coil with the help of a dimmer stat. The glass tube used for producing the jet can with- stand temperatures up to 400°C.

Objectives

To machine the glass workpiece in required profile using hot air from hot air jet machine

Outcome

Student will be provided an innovative method for machining of glass with hot air, which is a non-conventional machining process. The method can be used for machining of micro channels and micro features on glass workpieces. In the course of Micro and Nano Manufacturing for S8 ME, the same instrument can be preferred.

The video demonstration of Hot Air Jet Machine is uploaded in YouTube (a link is provided in the college website).

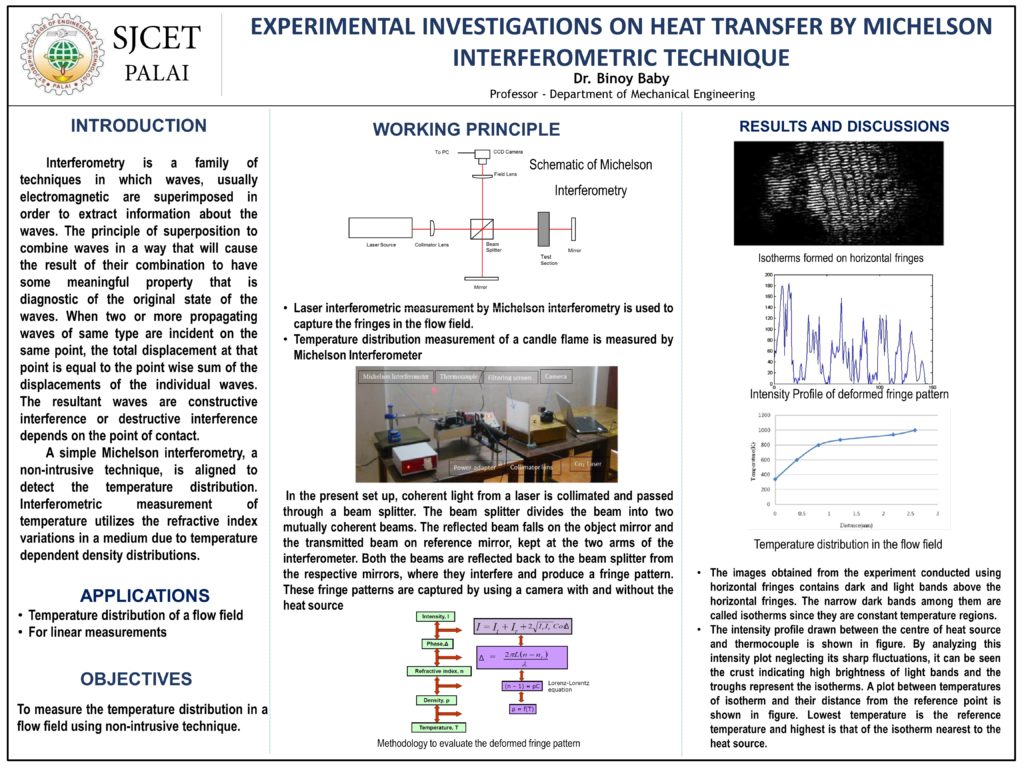

POSTER PRESENTATION OF MICHELSON INTERFEROMETRY

A simple Michelson interferometry, a non-intrusive technique, is aligned to detect the temperature distribution. Interferometric measurement of temperature utilizes the refractive index variations in a medium due to temperature dependent density distributions. Temperature distribution measurement of a candle flame is measured by Michelson Interferometer at Mechanical measurement lab of SJCET Palai. This poster is demonstrated in department website.

Objectives

To measure the temperature distribution in a flow field using non-intrusive technique. Laser interferometric measurement by Michelson interferometry is used to capture the fringes in the flow field.

Outcome

For small flow field like heat sinks, heat dissipating devices flame,heater, the intrusive techniques such as thermocouple intrusion is disturbing the flow field while taking the measurements. This non-intrusive technique is not disturbing the flow field while taking the measurements. So that the accurate values/measurements are obtained. In the course of compressible flow for S7 ME the same measurement technique is mentioned.

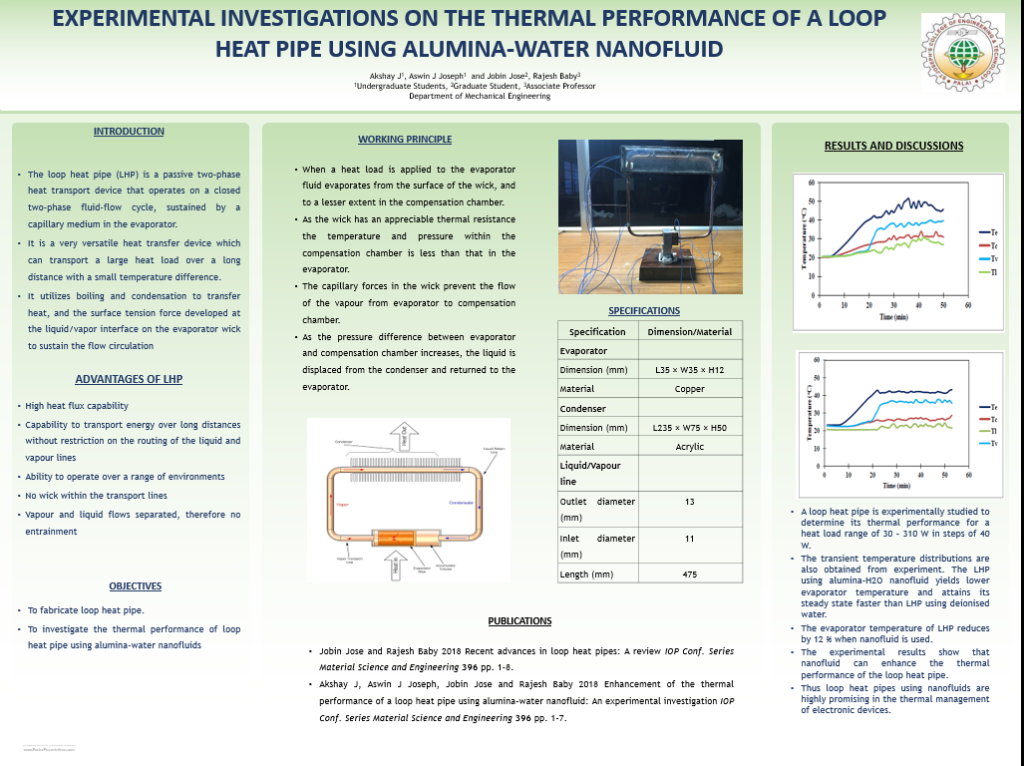

POSTER PRESENTATION OF CYLINDRICAL HEAT PIPES

Heat pipes are basic gadgets which are utilized to exchange heat starting from one area to the next, utilizing an evaporation-condensation cycle. Heat pipes are alluded to as the “superconductors” of heat because of their quick heat exchange capability with low heat loss. A poster presentation of cylindrical heat pipe is demonstrated in department website.

Objectives

• To determine the thermal characteristics of cylindrical heat pipes using alumina-water nanofluid.

• To determine the temperature distribution across the heat pipe.

Outcomes

Heat pipes can be used to transmit heat over significant distances with extremely negligible temperature drops and no external pumping power. Compared to the conventional heat transfer devices heat pipes are highly efficient with low energy consumption. In the course of heat and mass transfer for S6 ME , the introduction to heat pipes is explained. So this presentation will help to get an exposure in the heat pipe technology and temperature measurement using data acquisition system.

LABORATORIES

Design & Drawing Hall

Mechanical Workshop

Thermal Engineering Lab

Hydraulics Lab

Machine Tools Lab

CAD Lab

Mechanical Systems Lab

Measurements Lab

Heat Transfer Lab

Research Lab

Project Lab

Model Room

Museum

Industrial Engineering & Computational Lab

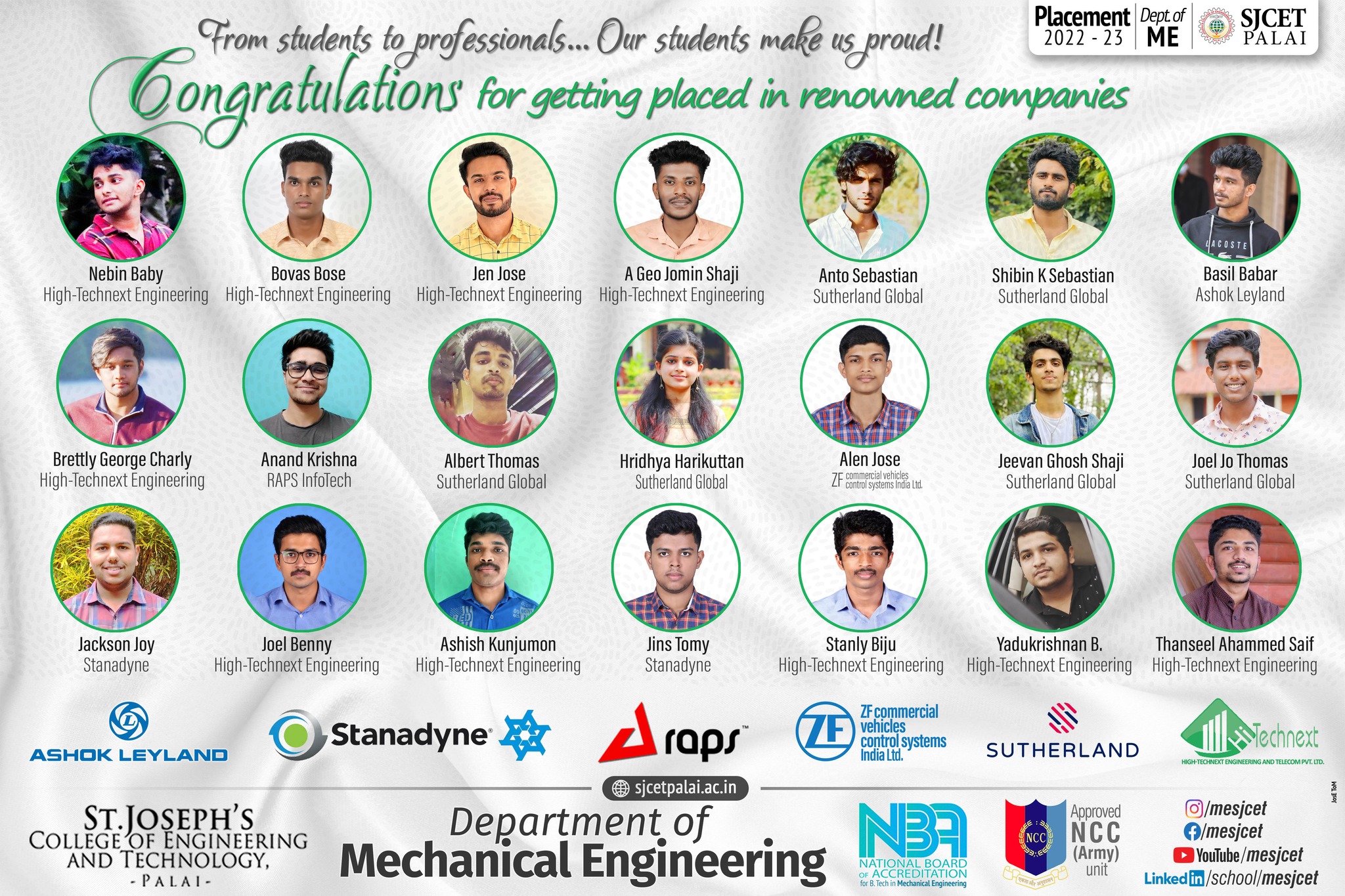

PLACEMENTS

| # | Name | Company |

|---|---|---|

| 1 | Emanuel K George | Mahindra |

| 2 | Manikutty Babu | Experion |

| 3 | Geo George | Infosys |

| 4 | Thushar Joshy | Infosys |

| 5 | Hari K Nair | Speridan |

| 6 | Hari Krishnan P G | HTC |

| 7 | Antony Jeswin Joseph | Faceperp |

| 8 | Albil T tommy | Acmegrand |

| 9 | Roshan P Jacob | Sutherland |

| 10 | Tinu Sajan | Sutherland |

| 11 | Aswin S | PEEPL Automation |

| 12 | Adhithya Biju | HTC |

| 13 | Genesis J Cheruvalli | Sutherland |

| 14 | Eva Antu | Renault-Nissan |

| 15 | Benchamin Tommy | Speridan |

| 16 | Alen P Baby | Sutherland |

| 17 | Sujith S | Acmegrand |

| 18 | Noel Saju | South Indian Bank |

| 19 | Naveen Tom Mathew | Sutherland |

| 20 | Albin Siby | image infosystem |

| 21 | Shinto kuriakose | Asianet |

| 22 | Thimothy benny | Acmegrade |

| 23 | Anish George | Acmegrade |

| 24 | Akhil krishnan | Acmegrade |

| 25 | Ben Roy | Oxygen Digital |

| 26 | Anandhu Venugopal | Oxygen Digital |

| 27 | Tom George | Oxygen Digital |

| 28 | Bestin baby | AAPL |

| 29 | Vishnu Vijayan | MRF Ltd |

| 30 | Amal Thomas | Mahindra and Mahindra Ltd. |

| 31 | Ayron Renny | TOYOTA , BANGALORE |

| 32 | Malcolm Samson Valiaparambil | Mahindra & Mahindra Ltd - AFS |

| 33 | Jubin Thomas | Peepl automation Pvt Ltd, |

| # | Student | Company |

|---|---|---|

| 1 | Jayadevu P R | TCSL |

| 2 | Ashish P Sushil | Sutherland Global Services Pvt Ltd |

| 3 | Avinash N Babu | SEPACK |

| 4 | Bevin Mathew | BOSCH |

| 5 | Abin Siji | TCSL |

| 6 | Robin Pious | PEEPL AUTOMATION PRIVATE LIMITED |

| 7 | Rony George | ANGLO EASTERN |

| 8 | Snehaj Sabu | PEEPL AUTOMATION PRIVATE LIMITED |

| 9 | Jose Tom | Horizon motors private Ltd |

| 10 | Amal Babu | CISF |

| 11 | Justin Mathew | TCSL |

| 12 | Navaneeth Krishnan | Sutherland Global Services Pvt Ltd |

| 13 | Nevil Thomas | SHILPI ENGINEERING PVT LTD |

| 14 | Joseph George | Micron Electricals |

| 15 | Ashish Jojo Manoor | TCSL |

| 16 | Jenithson Sebastian | FEDERAL BANK |

| 17 | Akshay Biju | TCSL |

| 18 | Robin Roy | APPOLO TYRES LTD |

| 19 | Hari Govind | RANDSTAD INDIA |

| 20 | Akhil S Mon Kurian | NCS Autohub Pvt Ltd |

| 21 | Sandra Susan Biju | FAURECIA |

| 22 | Akash joy | TCSL |

| 23 | Akshay shaji | COCHIN SHIPYARD LIMITED |

| 24 | Milen roy | QUEST |

| 25 | Sreejith S | APPOLO TYRES |

| 26 | Abu george | sutherland |

| # | Name | Company |

|---|---|---|

| 1 | Jithin Reji | Bentley Motors Limited |

| 2 | Victor Emmanuel Jose | Infosys |

| 3 | Nabeel | Trutuff Safety Glasses Private Limited |

| 4 | Mathews Mathew | ELSOL power solutions Pvt Ltd |

| 5 | Sajo Mathew | Department of industries and commerce |

| 6 | Tojo Thomas | Infosys |

| 7 | Sam Sabu | Cognizant technologies solutions India private limited |

| 8 | Naveen Francis | TATA ELXSI Limited |

| 9 | Adorn kurian | Cognizant Technology Solutions India private limited |

| 10 | Adarsh m nair | Ideal Engineering and construction |

| 11 | Edwin s panathanam | TECH –PRE Solutions Inc |

| 12 | Dibin C S | Kottayam District Trade centre |

| 13 | Daine Mathew | Infosys |

| 14 | Jijo jose | Kerala Water Authority |

| 15 | Gayathri Raj | Kottayam District Trade centre |

| 16 | Arjun t kanchiramattam | AIET INDIA Private Limited |

| 17 | Adith j pachen | Cognizant Technology Solutions India private limited |

| 18 | Vishnu namboothiri PT | Wheels india limited |

| 19 | Akhil A Kumar | Magnanimous design minds private limited |

| 20 | Autsin Sajai | FLOW TECH |

| 21 | Prejith krishna | Infosys |

| 22 | auseppachan | JP marine service |

| 23 | Melbin jose | Quilon REAL industries private limited |

| 24 | Tigin cherian | Pentagon |

| 25 | Karun Cherian | Infosys |

| 26 | Thomas sabu | Infosys |

| 27 | Krishna chand | MVA stratford |

| 28 | Joel jose | US Technology |

| 29 | Joel tom | Infusory |

| 30 | Aswin nair | HCL |

| 33 | S Hareesh | Pro station master |

| 34 | Aswin k ajith | HVAC trainee Engineer |

| 35 | Boby Naigil | Software engineer |

| 36 | Don cyriac | AME Co-op apprentice |

| # | Name | Company |

|---|---|---|

| 1 | Kevin saji thomas | Amazon |

| 2 | Sharath R | Hudi India Private limited |

| 3 | Tony kacham kodath rarichan | Quantzig Private Limited |

| 4 | Manu mohanan nair | Infosys |

| 5 | Karun kailas | MRF |

| 6 | Jinse jose | Dentcare dental lab private limited |

| 7 | Nakul Krishnan | Kerala Government |

| 8 | Soorya narayanan | TUV Rheinland |

| 9 | Razi Haroon | Energoprojekt Entel Ltd |

| 10 | Rincemon Reji | St Joseph’s College of EngineeringTechnology palai |

| 11 | Mathew George | Tech-Pre Concepts |

| 12 | Tomin siby | TribusPoint Software Private Limited |

| 13 | Nrupan Satheesh Krishnan | Infosys |

| 14 | Sony Chacko | Byju’s |

| 15 | George m kolethu | Startek private limited |

| 16 | Dani Alex Parayil | Black Lake Technologies |

| 17 | Rahul Oommen George | Tecnicas Reunidas |

| 18 | Vinayak Vijayan | Benzara Ecommerce |

| 19 | Zachariah Alex | Federal Bank |

| 20 | Karthik C Nair | Infosys |

| 21 | Shon Sunny | Walmart |

| 22 | Alwin JOY | Infosys |

| 23 | Shajan K S | Frijin steel Construction Middle East |

| 24 | Rinto K Thomas | Lynk Global |

| 25 | Venugopal Yadhukrishnan | Government of India |

| 26 | Rahul Raju Paul | Sutherland |

| 27 | Fredy Antony | Aarvi Encon Limited |

| 28 | Abhinav binulal | NAFFCO |

| 29 | Harishankar jayakumar | Infosys |

| 30 | Johny paulose | CRAIGHAVEN LTD |

| 31 | Mathew pius | Six dee telecom solution s private limited |

| 32 | Tom martin | kiwirail |

| 33 | Mathew Thomson | Peepl Automation Private limited |

| 34 | James s ottathil | Federal bank |

| 35 | Robish johnson | SHRIRAM |

| 36 | Sreehari jayakujmar | Incheon KIA |

| 37 | Dony babu | Reliance industries limited |

| 38 | Allwyn Kuruvila Ambat | Deccan hydraulics private limited |

| 39 | Deepak Ulahannan | Western interior designer and marine contractors |

| 40 | Gokul Krishnan | Executive ship management private limited |

| 41 | Christo Jose | Malabar steel and tubes |

| 43 | Rince Kurian | KADCO |

| 44 | Jeffin George | Sutherland |

| 45 | Antony K K | TOP HAVEN MOTORS |

| 46 | Arshad Biju | Ibssoftware |

| 47 | Jibin reji | Kerala Government |

| 48 | Jiffinnmathew chacko | Honda vision Motors |

| SL. NO. | NAME OF THE STUDENT | ENROLMENT NO. | NAME OF THE EMPLOYER | APPOINTMENT LETTER REFERENCE NO. WITH DATE |

|---|---|---|---|---|

| 1 | JOHN M T | 14019043 | SUTHERLAND GLOBAL SERVICES | OFFER LETTERDTD 14/04/2018 |

| 2 | JOSE T KALLUPURACKAL | 14019046 | PETROLINK DATA SERVICES PVT LTD. | OFFER LETTER DTD 25/07/2018 |

| 3 | JOSEPH STEVE MENDEZ | 14019048 | INFOSYS TECHNOLOGIES LTD | HRD/3T/18-19/12048372 |

| 4 | JOSHWIN THOMAS | 14019049 | IBS SOFTWARE | IBS/OFF/SE/11533 DTD 04/01/2018 |

| 5 | LIBIN THOMAS | 14019055 | IBS SOFTWARE | IBS/OFF/SE/11531 DTD 04/01/2018 |

| 6 | LISHON ABRAHAM | 14019056 | JINDAL STEEL PLANT | I.D NO.A000100886 |

| 7 | MATTHEW SAMSON | 14019061 | SUTHERLAND GLOBAL SERVICES | OFFER LETTER DTD 14/04/2018 |

| 8 | MINSHID HIFSU RAHMAN | 14019066 | SUTHERLAND GLOBAL SERVICES | OFFER LETTER DTD 14/04/2018 |

| 9 | NIKHIL ANTONY ROY | 14019067 | SUTHERLAND GLOBAL SERVICES | OFFER LETTER DTD 14/04/2018 |

| 10 | SHAWN JOBES MATHEW | 14019087 | SUTHERLAND GLOBAL SERVICES | OFFER LETTER DTD 14/04/2018 |

| 11 | SIDDHARTH P | 14019089 | WIPRO LIMITED | APPOINMENT LETTER DTD 22/11/2018 |

| 12 | STEVEN BIJU | 14019095 | INFOSYS TECHNOLOGIES LTD | HRD/3T/18-19/12048143 DTD 01/06/2018 |

| 13 | THOMSON TOM | 14019096 | EVOBI AUTOMATIONS | OFFER LETTER DTD 04/06/2018 |

| 14 | ABHIRAJ C R | 14018985 | SRIRAM FINANCE | CAN032626 DTD 10/04/2018 |

| 15 | AJIN ARAVINDH | 14018989 | KELACHANDRA MACHINES | 0201-KM/2018 DTD 12/06/2018 |

| 16 | ALEN BABY JACOB | 14019001 | SRIRAM FINANCE | CAN032624 DTD 10/04/2018 |

| 17 | ALLEN SIBY | 14019005 | GODREJ,INTERIO | HK/HR/TR-OFFER2018-19/TO-365 |

| 18 | AMAL JOSEPH | 14019009 | TCS | TCSL/DT20173877631/1167237/TRIVANDRUM |

| 19 | ANANDU V NAIR | 14019012 | SUTHERLAND GLOBAL SERIVES | OFFER LETTER DTD 14/04/2018 |

| 20 | ANOOP ALEXANDER | 14019014 | SRIRAM FINANCE | CAN032648 DTD 10/04/2018 |

| 21 | AUSTIN GEORGE | 14019019 | BYJUS | OFFER LETTER DTD 27/06/2018 |

| 22 | BONEY KURIAN | 14019023 | SUTHERLAND GLOBAL SERIVES | OFFER LETTER DTD 14/04/2018 |

| 23 | BIJO THOMAS | 14019021 | ARANCO INFRASTRUCTURE | EMPLOYEE I.D CARD |

| 24 | ABEL MATHEWS JACOB | 14018982 | NASER M.AL-BADDAH & PARTNER GEN TRADG & CONT.CO.W.L.L | 6587/LOCAL/11/18 |

| 25 | JIMMY JOY PALACKAL | 14019037 | OYO ROOMS INDIA PVT LTD | OFFER LETTER DTD 17/03/2018 |

| 26 | AKSHAY. J | 14018998 | SPM INDIA LTD | SELECTION LETTER DTD 15/12/2018 |

| 27 | JOE JOSEPH | 14019041 | LUNAR EXPORTS PVT LTD. | OFFER LETTER DTD 03/09/2018 |

| 28 | JOEL JOHNEY | 14019042 | DAERAT AL ESKAN EST,RIYADH,KSA | I.D 2162599472 |

| 29 | ALAN JOSEPH MATHEW | 14018999 | JENDAMARK, SOUTH AFRICA | 2018/078 DTD04/09/2018 |

| 30 | NOEL SIBY | 14019021 | ST.MARY’S RUBBERS PVT LTD | EMPLOYEE I.D CARD |

| 31 | SREEKESHNATH T R | 13019152 | MY-POCKET MART, ALAPPUZHA | ENTREPRENEUR-PARTNER |

| 32 | VARGHESE ULAHANNAN | 13019125 | MY-POCKET MART, ALAPPUZHA | ENTREPRENEUR-PARTNER |

| 33 | CLEVIN JOHN | 14019027 | TECHNO ROOF INSULATION EST.UAE | OFFER LETTER ,JUNE 25, 2018 |

| 34 | ALAN MATHEW | 14018999 | JENDAMARK | OFFER LETTER,2018/078 |

| 35 | JOJIN ALEX | 14019044 | TATA CONSULTANCY SERVICES,KOCHI | OFFER LETTER,TCS/DT2017 3962028 |

| 36 | THOMSON TOM | 14019096 | INFUSORY DESIGNS | ENTREPRENEUR-PARTNER |

| SL. NO. | NAME OF THE STUDENT | ENROLMENT NO. | NAME OF THE EMPLOYER | APPOINTMENT LETTER REFERENCE NO. WITH DATE |

|---|---|---|---|---|

| 1 | JOSEPH THOMAS | 13019114 | COCHIN SHIPYARD LTD. | LETTER DTD:10/01/2018 |

| 2 | JOSHIN JACOB | 13019115 | COCHIN SHIPYARD LTD. | EMP CODE:64479 |

| 3 | JUSTINE T E | 13019118 | BPCL, COCHIN | KR. REF P.24 GEN/16/12/2017 R.2592 |

| 4 | MANU THOMAS | 13019121 | HGS, HINDUSTAN GLOBAL SOLUTION | LETTER DTD:04/02/2017 |

| 5 | MATHEW TOM | 13019123 | APPOLLO TYRES, KALAMASSERY, COCHIN | EMP.CODE:19775 |

| 6 | MINIL ROY | 13019124 | HIGHGROUND ENTERPRISE LTD, MUMBAI | LETTER DTD:18/05/2018 |

| 7 | NAVIN A VIJAY | 13019127 | BPCL, COCHIN | BPCL/SR/AIP/EL APPNT REG NO:SKLG006170500600 |

| 8 | NEETHIN NANDAKUMAR | 13019128 | INFOSYS TECHNOLOGIES LTD | HRD/3T/17-18/11525454,14/11/2017 |

| 9 | NESEEF AZEEZ | 13019129 | COCHIN SHIPYARD LTD. | EMP. CODE:64143(T5920) |

| 10 | NIDHIN BABY | 13019130 | BPCL, COCHIN | BPCL/SR/APP/EL(SKLG006170500897 |

| 11 | NIKHIL T ABRAHAM | 13019131 | APPOLLO TYRES, KALAMASSERY, COCHIN | EMP.CODE:20518 |

| 12 | PAUL MANUEL | 13019135 | TVS-SFL,PONDICHERRY | CWG/1200001DTD;4/06/2018 |

| 13 | PAVAN THOMAS | 13019137 | TVS-SFL,PONDICHERRY | CWG/1200001DTD;15/06/2018 |

| 14 | RIJO C RAJU | 13019139 | POWER WRAP MIDDLE EAST INDUSTRIES, RAS AL-KHAIMAH | LETTER DTD 26/10/ 2017 |

| 15 | ROBIN TOMY | 13019140 | MYOUNG SHIN INDIA, CHENNAI | EMPLOYEE NO:H1947 |

| 16 | ROJIN JOSE KARIYIL | 13019141 | QATAR ENGINEERING & CONSTRUCTION | EMP TOKEN NO:96628 |

| 17 | SACHIN TOM | 13019144 | ALFA PEB LTD, BANGALORE | APPOINTMENT LETTER DTD 01/06/2018 |

| 18 | SIJO K PHILIP | 13019150 | APPOLLO TYRES, KALAMASSERY, COCHIN | I.D NO:19782 |

| 19 | SOORAJ C | 13019151 | TVS-SFL, PONDICHERRY | CWG/1200001 DTD 15/SEP/2018 |

| 20 | SUBIN KURUVILLA | 13019155 | OMAN SHAPOORJI COMPANY, LLC MUSCAT | EMP NO.4364 |

| 21 | TENY MATHEW | 13019158 | TVS-SFL, PONDICHERRY | CWG/1200001 DTD 15/09/2018 |

| 22 | TIJO THOMAS JOHN | 13019160 | INSULATION DYNAMICS TRADING & CONTRACTING W.L.L, QATAR | JOINING REPORT DTD,27 AUGUST 2017 |

| 23 | TOM K THOMAS | 13019161 | INSTANTPOST PVT. LTD, BANGALORE | LETTER DTD:28/02/2018 |

| 24 | TOMIN AUGUSTINE | 13019162 | TVS-SFL, PONDICHERRY | CWG/1200001 DTD15/SEP/2018 |

| 25 | VIKRANTH D | 13019166 | INFOSYS TECHNOLOGIES LTD | HRD/3T/17-18/11525062, 14/11/2017 |

| 26 | VILAS PHILIP | 13019167 | IBS, COCHIN | IBS/OFF/SE/10688,1/1/2017 |

| 27 | VINEETH SEBASTIAN PHILIP | 13019168 | INFOSYS TECHNOLOGIES LTD | HRD/3T/17-18/115211811 |

| 28 | VINI JOHN | 13019169 | IBM, BANGALORE | REF NO:1634736 |

| 29 | YADUKRISHNA T | 13019171 | ENVENTURE ENGINEERING LLP, BANGALORE | HR/ENU 7020218 |

| 30 | ROGY MATHEW | 13019175 | SRC CHEMICALS, PUNE | EMP CODE:A13 |

| 31 | RAHEES N K | 12018602 | TVS-SFL, PONDICHERRY | CWG/1200001 DTD 15/09/2018 |

| 32 | ABRAHAM MATHEW | 13019053 | IBM,BENGALURU | I D CARD IBM |

| 33 | AKHIL GOVIND P | 13019057 | ALFA PEB LTD, BEGALURU | LETTER DTD17/08/2018 |

| 34 | ALBIN MICHAEL | 13019062 | V-GUARD INDUSTRIES LTD | LETTER DTD:16/10/2017 |

| 35 | AMAL ABRAHAM | 13019065 | INFOSYS TECHNOLOGIES LTD | HRD/3T/17-18/11522154,5/1/2018 |

| 36 | AMAL BABY | 13019066 | IBS,TRIVANDRUM | IBS/OFF/SE/10687, 13/12/2016 |

| 37 | ANAND KRISHNA | 13019069 | FEDERAL BANK LTD | HR/B/PR-36211/PC/A-159/74055/2017-18, 23/5/2017, |

| 38 | ARUN SOJAN | 13019076 | CONCORD AIR CONDITIONING SYSTEMS AND SOLUTIONS | 50000268040001000,1/3/2018 |

| 39 | ASHIN JOSEPH | 13019077 | IBS,TRIVANDRUM | IBS/OFF/SE/10690,1/1/2017 |

| 40 | B .NIHAL | 13019079 | V-GUARD INDUSTRIES LTD | LETTER DTD:16/10/2017 |

| 41 | BALAMURALIKRISHNAN K | 13019081 | HNL, VELLOOR, KOTTAYAM. | HNL/HRD/23/18,7/2/2018 |

| 42 | BASHEK.M.K | 13019082 | S.R AUTO INDUSTRIES | LETTER DTD:01/01/2018 |

| 43 | CHRISTIE DAVIS | 13019089 | INFOSYS TECHNOLOGIES LTD | HRD/3T/17-18/11522174,14/11/2017 |

| 44 | DARSHAN PRATHEEP | 13019090 | SOUTH INDIAN BANK LTD | HRD:131:2018-19DATED 16/04/2018 |

| 45 | GISHNU SIVAN | 13019095 | INSTRUMENTATION LTD,PALAKKAD | ILP/PERS/RECTT/APP/2017,8/11/2017 |

| 46 | JIBIN JOHNY | 13019103 | TRANSRAIL LIGHTING LTD BOMBAY | TLL/HR/2018/03 |

| 47 | JITHU SREENIVAS | 13019107 | TECHNOMECH ELECTROMECHANICAL WORKS L.L.C DUBAI | ENTRY PERMIT NO:2257055/2018/201,10/5/2018 |

| 48 | CHRIS ANTO | 13019088 | INSTANT POST PRINTERS AND SCANNERS PVT. LTD. BANGALORE | LETTER DTD:28/02/2018 |

| 49 | JABIN MANU JOSE | 13019099 | SUTHERLAND GLOBAL SERVICES PVT LTD. | LETTER DTD:25/07/2017 |

| 50 | JOBIN MATHEW | 13019109 | FIRST SOURCE SOLUTIONS,BANGALORE | LETTER DTD:1207/2018 |

| 51 | ABIN THOMAS | 13019052 | LALIT PIPES & PIPE, KALYAN, MAHARASHTRA | LETTER DTD,29/09/2018 |

| 52 | AKSHAYJITH R | 13019059 | APOLLO TYRES,, KERALA | EMPLOYEE CODE: 21573 |

| 53 | ARUN C ANIL | 13019059 | ECOSUN , ALAPPUZHA | ENTREPRENEUR |

| 54 | ELVIN PIOUS | 13019093 | MSR GROUP GENERAL TRADING AND CONTRACTING COMPANY WLL ,KUWAIT | MSR/2018/06,25/06/2018 |

| 55 | ARUN RAJENDRAN | ALUMINIUM INDUSTRIES LTD. | May 28, 1900 |

| SL. NO. | NAME OF THE STUDENT | ENROLMENT NO. | NAME OF THE EMPLOYER | APPOINTMENT LETTER REFERENCE NO. WITH DATE |

|---|---|---|---|---|

| 1 | ABIN STEPHEN | 12018503 | SUTHERLAND GLOBAL SERVICES | OFFER LETTER DTD 06/05/2016 |

| 2 | ABISHEK MATHEWS | 12018504 | AL SHAHBIAH ENG.CO.L.L.C,SHARJA | LETTER DTD,2018,10897617,27/06/2016 |

| 3 | ABY TOM | 12018505 | INFOSYS | 10897617 27/06/2016 |

| 4 | AKSHAY JOSEPH | 12018510 | GOOD METHODS GLOBAL SOFT WARE SOLUTIONS.LTD. | OFFER LETTER DTD 15/12/2016 |

| 5 | ALBIN MATHEW | 12018511 | ABDUL RAHIM ARCHITECTURAL CONSULTANTS | WORK PERMIT NO:75298806 |

| 6 | ANANTHADEV D | 12018516 | SUTHERLAND GLOBAL SERVICES | OFFER LETTER DTD 06/05/2016 |

| 7 | ANOOP M | 12018519 | KITEX GARMENTS LTD | LETTER DTD:25/04/2017 |

| 8 | ANSHIF ALI | 12018520 | CORNER STONE INTERIORS | CID/010/HRD/04/17,6/4/2017 |

| 9 | ANWIN ANAND ISAAC | 12018521 | SUTHERLAND GLOBAL SERVICES | OFFER LETTER DTD 06/05/2016 |

| 10 | RUSHIL REUBEN JACOB | 1208609 | INFOSYS | HRD/3T/16-17/10897465 DTD 17/01/2017 |

| 11 | ARUN C ABRAHAM | 12018524 | INFOSYS | HRD/3T/16-17/10897631, 24/11/2016 |

| 12 | ASHVIN JACOB GEORGE | 12018526 | RAJASHREE MOTORS PVT. LTD. ERANAKULAM | OFFER LETTER DTD01/2/2018,10897638 |

| 13 | BASIL C BABY | 12018529 | INFOSYS | 10897638, 23/03/2017 |

| 14 | BOBY C. JOHN | 12018531 | SPERDIANTECHNOLOGIES PVT. LTD. | OFFER LETTER DTD .22/08/2016 |

| 15 | CHACKO MATHEW | 12018533 | FILLTRONICS AUTOMATION | VISITNG CARD |

| 16 | CHRISTY JOHNY | 12018534 | SUTHERLAND GLOBAL SERVICES | OFFER LETTER DTD 06/05/2016 |

| 17 | DENNIES JOHN | 12018535 | SUTHERLAND GLOBAL SERVICES | OFFER LETTER DTD 06/05/2016 |

| 18 | FIJO M P | 12018542 | PINNACLE MOTOR WORKS PVT LTD | OFFER LETTER DTD,8/8/2017 |

| 19 | GOPIKRISHNAN S | 12018547 | UST GLOBAL | OFFER LETTER DTD 03/01/2017,EMPLOYEE I.D NO.63021 |

| 20 | JOBIN PHILIP | 12018567 | UST GLOBAL | HR/2017/U5647,20/03/2017 |

| 21 | JACOB LIGIL M K | 12018553 | OVERSEAS CONSTRUCTION CORPORATION | OCC/487/17178,17/03/2018 |

| 22 | JACOB THOMAS | 12018554 | JUMA MUBARAK KHAMIS JOWHAR ALSUWHIDI, UAE | ST16344962AE,10/12/2016 |

| 23 | JOSE PAUL | 12018572 | APPOLLO TYRES, TRISSUR | CLOCK NO A 4376 |

| 24 | JERMIS JOY | 12018558 | KITEX GARMENTS LTD | OFFER LETTER DTD 22/10/2016 |

| 25 | HARRY T CHIRAYIL | 12018549 | UST GLOBAL | HR/FRESH/2016/UST-10-JAN-2017-023,10/1/2017 |

| 26 | JIBY GEORGE | 12018560 | FRANKLIN TECHNICAL SERVICE,COCHIN | EMP CODE:124H21 |

| 27 | JISHNU P | 12018563 | INFOSYS TECHNOLOGIES LTD | HRD/3T/16-17/10897454,17/01/2017 |

| 28 | THOMAS MATHEW | 12018617 | TCS | TCSL/DT20153010476,23/03/2016 |

| 29 | ALPHONS JOY | 12018580 | YORK LIFT, UAE | LETTER DTD:10/07/2018 |

| 30 | JOTHIN C JOSE | 12018575 | REDLANDS ,TRISSUR | RMPL/01/2016/10,30/12/2016 |

| 31 | JOEL JOHN JOHNY | 12018568 | BARQ, QUATAR | BCG/HR/OL/BV24/17 |

| 32 | KEVIN AUGUSTINE | 12018581 | INDIGO AIRLINES | I.D CARD . |

| 33 | ROHIT RAVEENDRAN | 12018607 | SUTHERLAND GLOBAL SERVICES | OFFER LETTER DTD 06/05/2016 |

| 34 | JOMY JOSEPH MATHEW | 12018571 | SUTHERLAND GLOBAL SERVICES | OFFER LETTER DTD 06/05/2016 |

| 35 | SONU SANJEEVAN | 12018613 | SUTHERLAND GLOBAL SERVICES | OFFER LETTER DTD 06/05/2016 |

| 36 | JISS JOSE | 12018665 | ALLIES FIRE SYSTEM, KERALA | OFFER LETTER DTD 04/04/2017 |

| 37 | JOMY JOSEPH MATHEW | 12018571 | GIRI SYSTEMS PVT. LTD, CHENNAI | OFFER LETTER DTD 04/12/2017 |

| 38 | ATHUL C R | 12018527 | CARBORUNDUM UNIVERSAL LIMITED, KALAMASSERY | OFFER LETTER DTD25/05/2018 |

| 39 | MANU JOHN | 12018586 | MRF, CHENNAI | OFFER LETTER DTD 19/06/2017 |

| 40 | NOEL SOJAN | 12018598 | CONTROL & APPLICATIONS EMIRATES,UAE | LETTER DTD:02/05/2017 |

| 41 | ROHIT MATHEW | 12018606 | SUTHERLAND GLOBAL SERVICES | OFFER LETTER DTD:25/02/2016 |

| 42 | NIBIN BINU | 12018595 | APPAREL GROUP | EMP. CODE 118945 |

| 43 | AJAY PRAKASH | 12018507 | OVERSEAS CONSTRUCTION CO. | OCC/487/17208,17/03/2018 |

| 44 | RONALD P CHERIAN | 12018608 | HE-MAN AUTO ROBO PARK, TRIVANDRUM | I.D CARD NO :1038 |

| 45 | HARIKRISHNAN T.R | 12018615 | GEEYEM MOTORS LTD. | OFFER LETTER DTD 13/07/2018 |

| 46 | PRANNOY ROY | 12018584 | ONSHORE CONSTRUCTION COMPANY PVT LTD. | OCCPL-TE-037/OFFER/2017-18 |

| 47 | LIBIN P SCARIA | 12018584 | NAFFCO, UAE, DUBAI | OFFER LETTER DTD 05/05/2018 |

| 48 | PRAVEEN GEORGE | 12018600 | ALEGO FIRE SYSTEMS,THRISSUR | LETTER DTD; 20/12/2018 |

| 49 | JOVIL C MURICKEN | 12018576 | JBM AUTO SYSTEMS PVT. LTD | SALARY CARD DTD 30/04/18 |

| 50 | SANAD ABOOBACKER | 12018610 | PARISON’S ROLLER FLOUR MILLS PVT LTD. CALICUT | E/O/99/2017,22/12/2017 |

| 51 | IWIN JAMES | 12018551 | HINDHUSTAN NEWSPRINT | HNL/HRD/23/18,7/2/2018 |

| 52 | BIBIN ABRAHAM | 12018530 | ALTERNEIT LIFESTYLES PVT LTD | ALTERNEIT/PRO TRAI/02/SEP18 |

| 53 | J.AMALDEV | 12018552 | AAG INDIA PVT LTD | LETTER DTD 28/12/2018 |